The National Electrical Manufacturers Association (NEMA) is a US Manufacturers Organization which actively promotes standardized product specifications for electrical apparatus. While NEMA does not actually test products, it establishes the performance criteria for enclosures intended for specific environments. NEMA standards describe each type of enclosure in general and functional terms, and specifically omits reference to construction details. In other words, NEMA specifies what an enclosure must do, not how to manufacture it. This is also true about the EN 60.529/IEC 529. NEMA performance criteria and test methods are used by Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) as guidelines for investigation and listing of electrical enclosures. The tested enclosures are then authorized to carry a label by UL or CSA to prove it has passed the required tests and meets the applicable UL and CSA standard.

NEMA Classifications

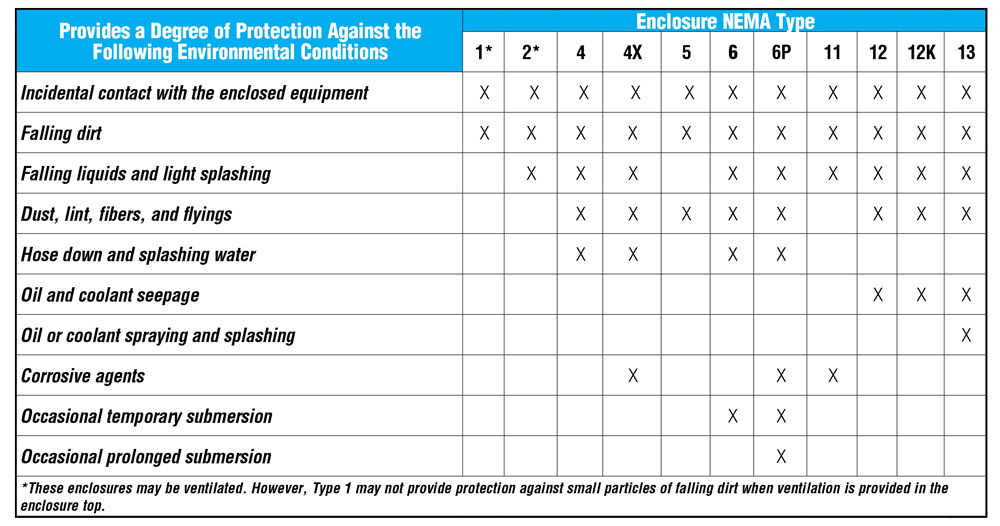

NEMA 1 enclosures are typically used for protecting controls and terminations from objects and personnel. This style of enclosure, while offering a latching door, does not have a gasketed sealing surface. NEMA 1 enclosures are used in applications where sealing out dust, oil, and water is not required.

NEMA 2 enclosures are intended for indoor use primarily to provide a degree of protection against limited amounts of falling water and dirt.

NEMA 3 enclosures are intended for outdoor use primarily to provide a degree of protection against windblown dust, rain, sleet, and external ice formation.

NEMA 3R enclosures are typically used in outdoor applications for wiring and junction boxes. This style of enclosure provides protection against falling rain, sleet, snow, and external ice formation. Indoors they protect against dripping water. This style of enclosure does not have a gasketed sealing surface. Some models have hasps for padlocking.

NEMA 3S enclosures are intended for outdoor use primarily to provide a degree of protection against windblown dust, rain, sleet, and to provide for operation of external mechanisms when ice laden.

NEMA 4 enclosures are used in many applications where an occasional washdown occurs or where machine tool cutter coolant is used. They also serve in applications where a pressurized stream of water will be used. NEMA 4 enclosures are gasketed and the door is clamped for maximum sealing.

NEMA 4X enclosures are made of stainless steel, aluminum, fiberglass, or polycarbonate. NEMA 4X enclosures are used in harsh environments where corrosive materials and caustic cleaners are used. Applications include food, such as meat/poultry processing facilities, where total washdown with disinfectants occur repeatedly, and petro-chemical facilities, including offshore petroleum sites.

NEMA 5 enclosures are intended for indoor use primarily to provide a degree of protection against settling airborne dust, falling dirt, and dripping non-corrosive liquids.

NEMA 6 enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against the entry of water during occasional, temporary submersion at a limited depth.

NEMA 6P enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against the entry of water during prolonged submersion at a limited depth.

NEMA 11 enclosures are intended for indoor use primarily to provide, by oil submersion, a degree of protection to enclosed equipment against the corrosive effects of liquids and gases.

NEMA 12 enclosures are intended for indoor use to provide a degree of protection against drips, falling dirt, and dripping non-corrosive liquids. NEMA 12 enclosures are most commonly used for indoor applications of automation control and electronic drives systems, including packaging, material handling, non-corrosive process control, and manufacturing applications. Gasketed doors seal the enclosure’s contents from airborne contaminants and non-pressurized water and oil.

NEMA 12K enclosures with knock-outs are intended for indoor use primarily to provide a degree of protection against dust, falling dirt, and dripping non-corrosive liquids other than at knock-outs.

NEMA 13 enclosures are intended for indoor use primarily to provide a degree of protection against dust, spraying of water, oil, and non-corrosive coolant.

What Do The NEMA Ratings Mean?

Comparison of Non-Hazardous Applications for Indoor Locations

The European IP Code

European Union members use the EN60.529/IEC 529 standard to classify an enclosure’s protection against various hazards. This system has been adopted by many other countries outside of Europe. The ingress protection (IP) system uses a two-digit code to describe the enclosure’s protection capabilities. The first digit signifies the protection level against solid objects, including dust. The second digit represents the enclosure’s degree of protection against ingress of water. The two-digit code is preceded by the prefix “IP.”

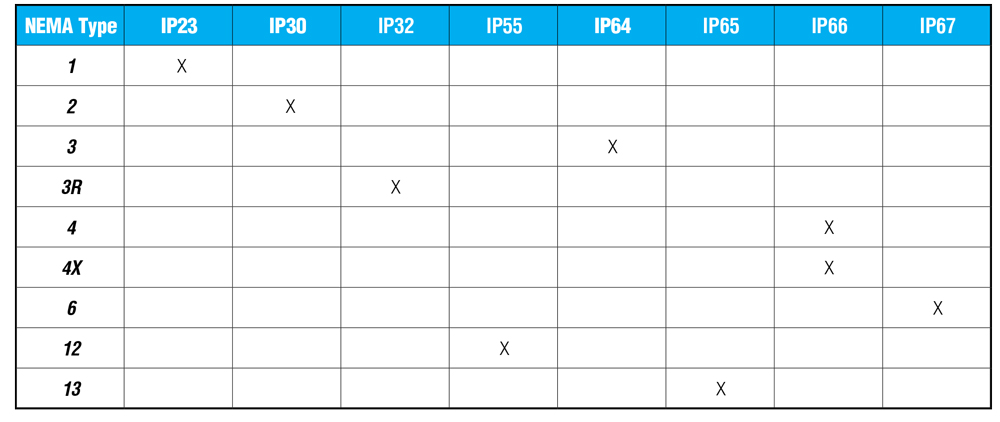

The cross-referenced table on the next pages is an approximate comparison of NEMA and International Electrotechnical Commission (IEC) classifications. It is offered for reference only. Please consult the appropriate standards for a full description of the requirements for each classification.

NEMA to IEC - Enclosure Rating Cross Reference*

*Note: This cross-reference table is an approximation of NEMA and IEC classifications for reference only. Please consult the appropriate agency’s requirements and test qualifications for complete information.