Trident® Industrial Control Panels

Quote Request

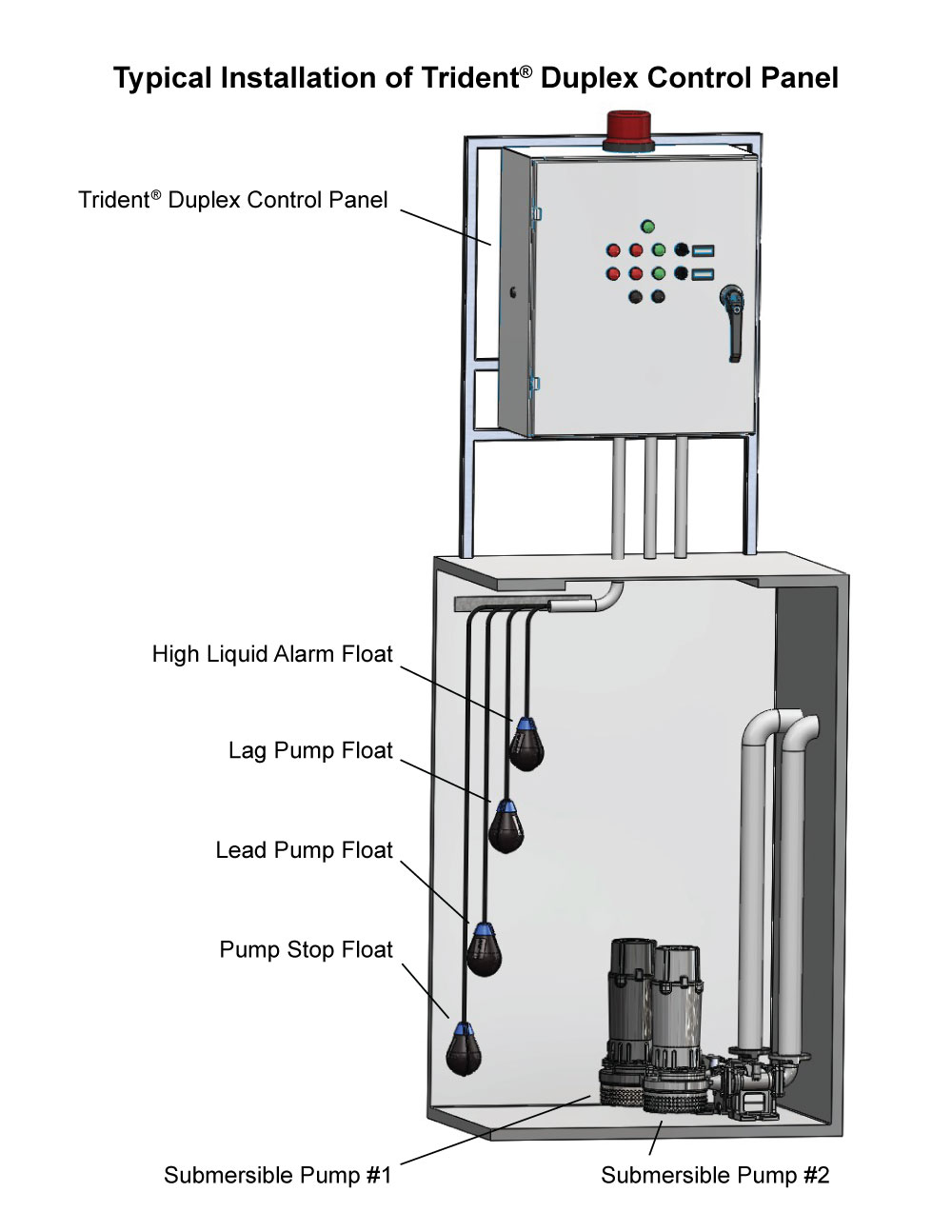

The Trident® control system is an industrial control panel designed to simplify pump stations. We incorporate the Modicon PLC for control logic and include industry communications, such as Modbus TCP and BACnet®. The Trident® utilizes a power base that allows for easy overload changes. In addition, these control systems come standard with Seal Fail and Thermal Cutout Pump protection.

| Model | Description | Full Load Amps | |

| TRS | Simplex | (Adjustable Overloads from 1.25 to 32.0 FLA) | |

| TRD | Duplex | (Adjustable Overloads from 1.25 to 32.0 FLA) | |

| TRT | Triplex | (Adjustable Overloads from 1.25 to 32.0 FLA) | |

| (Overloads sold separately: Simplex systems require 1 overload, duplex systems require 2 overloads, and triplex systems require 3 overloads.) | |||

| T11 | Single Phase 120/208/240 VAC | Adjustable overloads 1.25-5.0 | |

| T12 | Single Phase 120/208/240 VAC | Adjustable overloads 3.0-12.0 | |

| T13 | Single Phase 120/208/240 VAC | Adjustable overloads 8.0-32.0 | |

| T31 | Three Phase 208/240/480 VAC | Adjustable overloads 1.25-5.0 | |

| T32 | Three Phase 208/240/480 VAC |

Adjustable overloads 3.0-12.0 |

|

| T33 | Three Phase 208/240/480 VAC | Adjustable overloads 8.0-32.0 | |

Add Pump Portal® remote pump monitoring to this control panel! LEARN MORE

Features

- NEMA 3R rated painted steel enclosure with a lockable latch and dead-front inner door

- IEC rated motor starter with adjustable overload

- Pump control visible indicators: 22mm Pump #1 and #2 hand-off-auto (H.O.A.) switch, green pump run lights, red pump fault lights, and power on light

- Alarm visible indicators: Red beacon alarm light, and seal fail leak alarm test and silence buttons

- Alarm horn sounds 85 decibels at 10 feet

- Float operation:

- Simplex: Off, On, High Level

- Duplex: Off, Lead, Lag, High Level

- Triplex: Low Level, Off, Lead, Lag, Lag/Lag, High Level

- Elapsed time meters

- System Integration: Supports Modbus RTU/TCP, BACnet® MSTP/IP

- UL 508A listed

- Two-year limited warranty

- Easy access to webserver

- Flip switch for transducer and float mode

Applications

- Wastewater, Stormwater and Industrial Lift Stations

- Commercial

- Municipal

Custom Options

- 5 = Level Transducer, 5 PSI, Max Water Level 11 ft., Type: Wastewater

- 10 = Level Transducer, 10 PSI, Max Water Level 23 ft., Type: Wastewater

- 15 = Level Transducer, 15 PSI, Max Water Level 35 ft., Type: Wastewater

- 20 = Level Transducer, 20 PSI, Max Water Level 46 ft., Type: Wastewater

- 10X = Intrinsically Safe Level Transducer, 10 PSI, Maximum Water Level 23', Type: Wastewater, 50' Cable

- 20X = Intrinsically Safe Level Transducer, 20 PSI, Maximum Water Level 46', Type: Wastewater, 50' Cable

Note: The Trident® with transducer will come standard with backup floats (3 for simplex systems, 4 four duplex systems, and 5 for triplex systems).

- AF = Alarm Flasher

- AH = Anti Condensation Heater

- BB = Battery Backup 5 Ah

- C = Additional Cord Length Per Foot Per Component*

- CO = Convenience Outlet (User to supply 120 VAC)

- GR = Generator Receptacle, Includes Transfer Switch (Total Amps 125 Max)

- IS = Intrinsically Safe - Simplex

- ISD = Intrinsically Safe - Duplex

- IST = Intrinsically Safe - Triplex

- LA = Lightning Secondary Surge Arrestor

- MD = Main Disconnect - Through Door Style

- PM = Phase Monitoring - Ph Loss, Ph Unbalance, Undervoltage, Overvoltage

- PX = Pump Portal® Wireless Remote Panel Control and System Monitoring

- RPRO = Radar Sensor, Max Level Range 32', 4-20mA + RS485, 12-30VDC, 50' Cable

- S3 = No Floats

- SS4 = Upgraded Enclosure (304 Stainless Steel)

- SS6 = Upgraded Enclosure (316 Stainless Steel)

- UPRO = Ultrasonic Sensor, Max Level Range 15', 4-20mA, 12-30VDC, 50' Cable

*Additional cord length greater than 20’: Specify after C. Example: (TRD-T31-C50) Indicates 50’ cord lengths for all floats.

**Additional fee will apply for annual subscription

Note: Example when adding options to the TRD panel: TRD-T31-PX-SS4

Trident® Webserver

Our Trident® industrial control system features a comprehensive webserver with our Pacific 2.0 software that allows for complete customization and monitoring of the system.

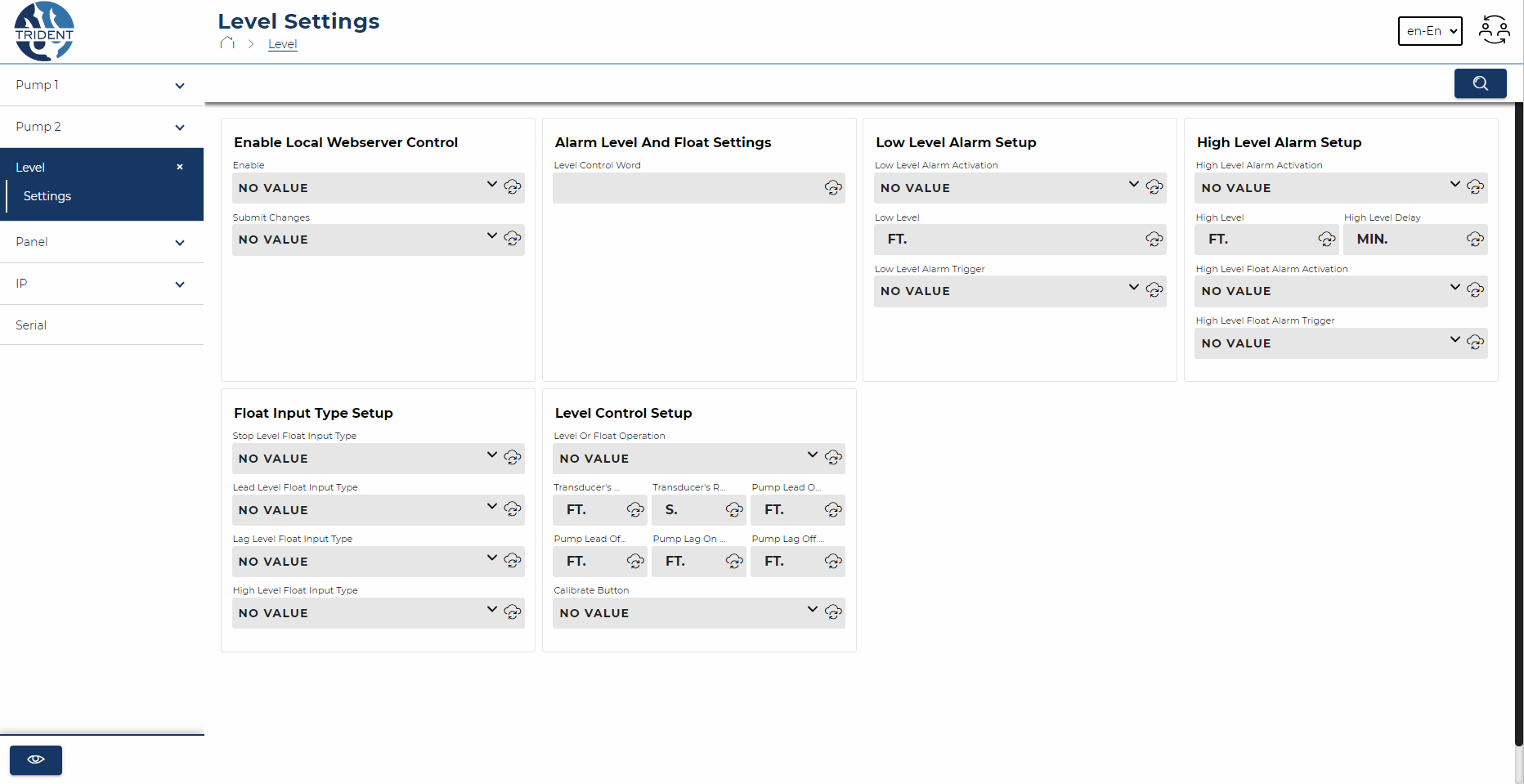

Level Settings

This page allows you to adjust the level and float settings and configure the level alarms.

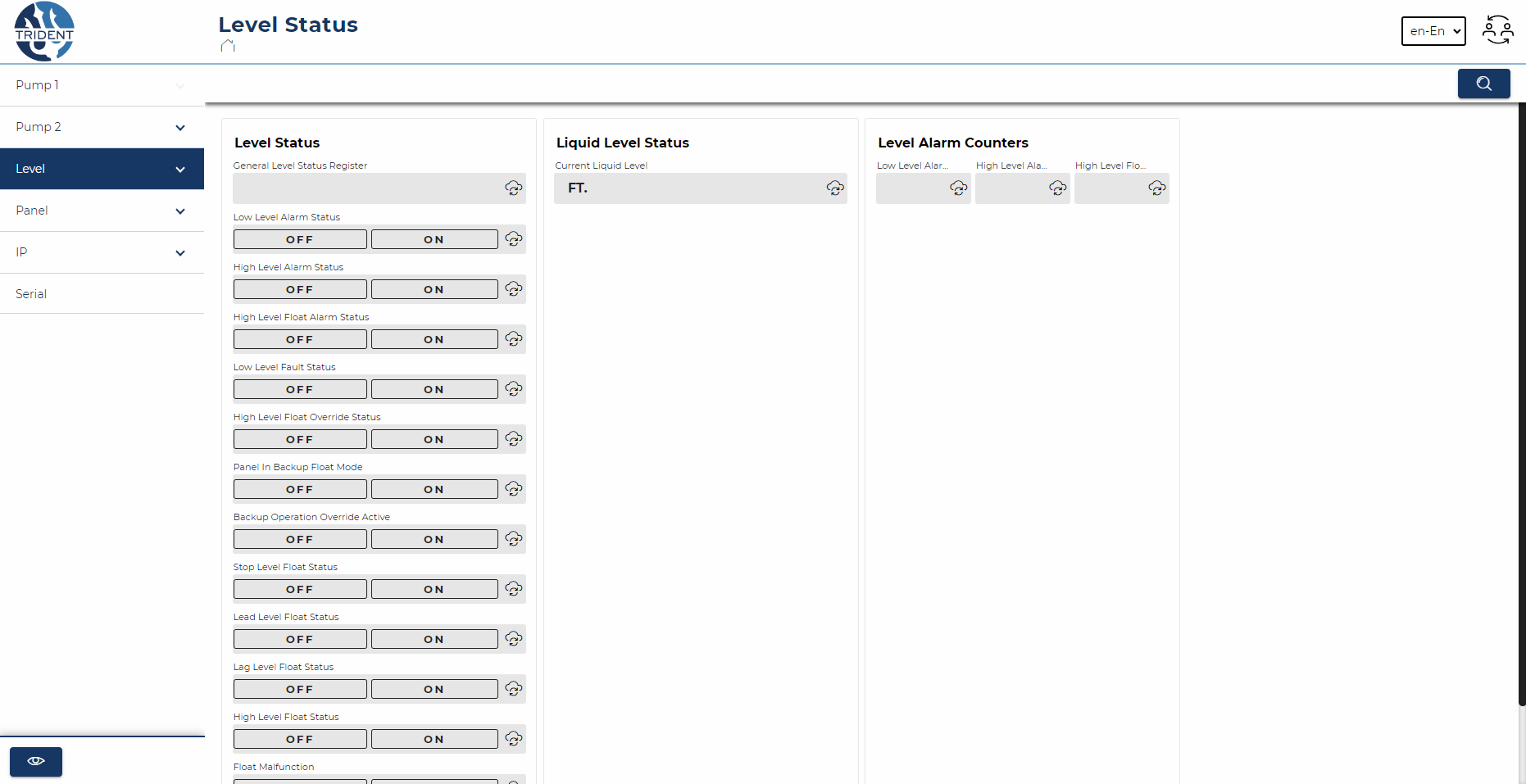

Level Status

This page displays the current state of each level register, the current liquid level from a transducer (if applicable), and the count of liquid level alarms.

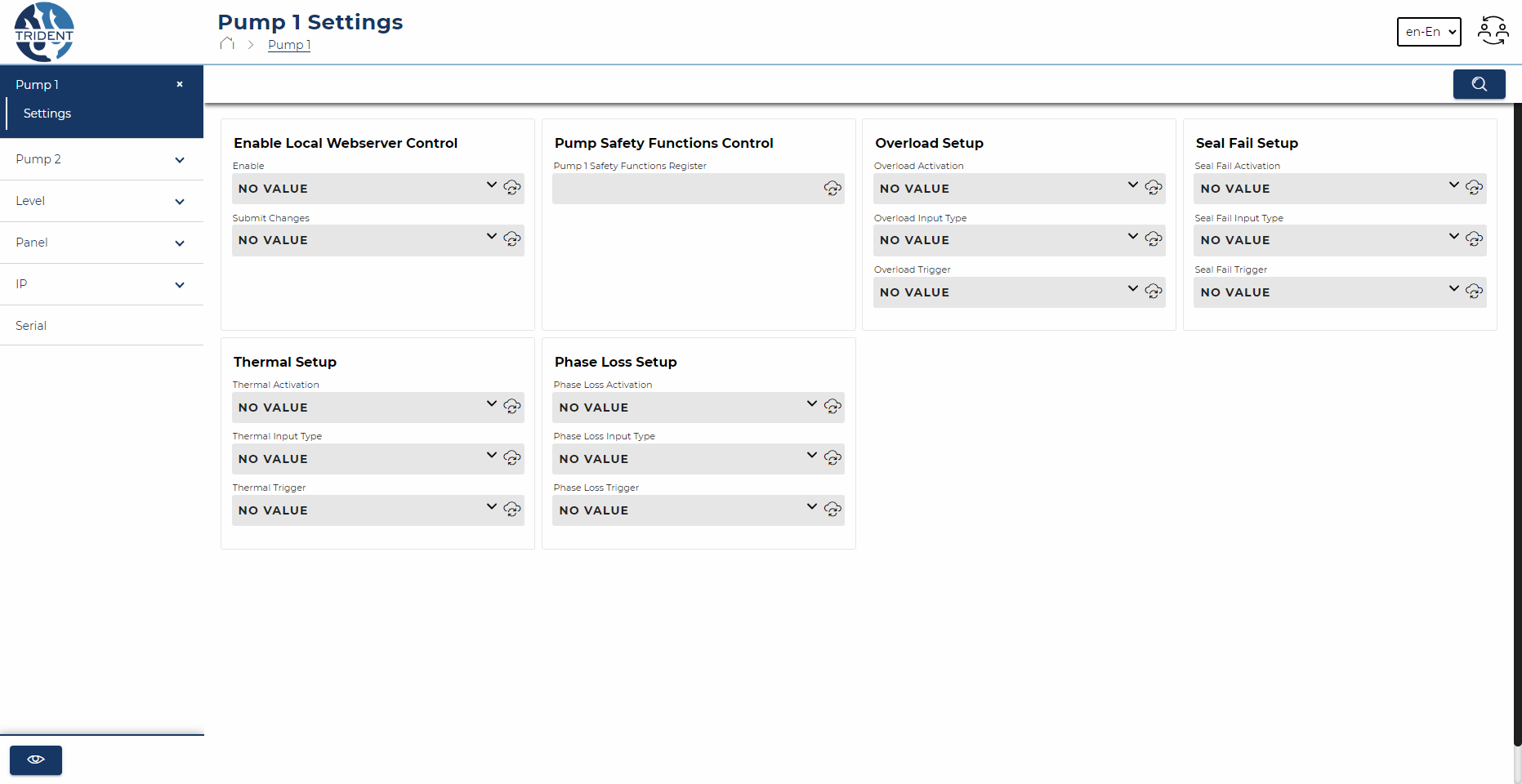

Pump Status

This page allows you to view the pump safety register and configure the pump safety features.