Liquid Smart® Panels

Quote Request

Literature

OSSIM-30-OR

OSSIM-30-OR-2

OSSIM-TP-3-OR

OSSIM-TP-3-OR-2

Pump Water, Not Oil.™

Liquid Smart® pump panels are designed to meet industrial and elevator code special applications that require the responsible removal of oil and water. The systems are setup to automatically pump water to the normal discharge area and pump oil to a secondary containment area. They are also compliant with Elevator Code ASME A17.1 and state/federal regulations.

Features

- UL Listed for the United States and Canada

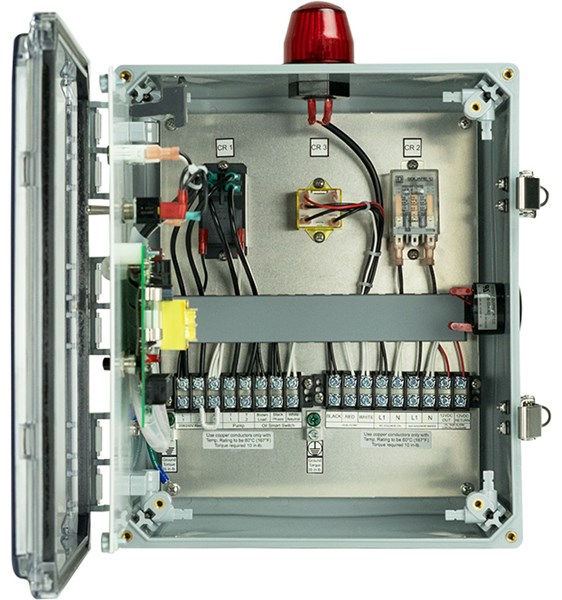

- NEMA 4X rated polycarbonate enclosure with lockable latches

- Pump control visible indicators: Pump #1 hand-off-auto (H.O.A.) switch, green Pump Run light, and green Power On light

- Alarm visible indicators: Red beacon alarm light, yellow light for oil, white light for water, alarm test and silence buttons

- Alarm horn sounds at 85 decibels at 10’

- Complete panel remote monitoring dry contacts: Oil, Water, High Liquid

Applications

- Elevator sumps

- Electric utilities (substations, power plants, underground vaults, and transformer barriers)

- Manufacturing facilities

- Any application where there is a need to remove water and oil

Why Oil Smart?

- The Oil Smart® system uses capacitive sensors that are factory-calibrated for immediate operation to differentiate between oil and water. In contrast to conductive sensors, capacitive sensors are insulated by oil and do not require ongoing maintenance.

- Unlike other systems that utilize error prone floats as their primary oil and water sensors, Oil Smart® technology uses reliable solid-state sensors that do not require any moving parts. In addition, See Water’s Oil Smart® sensors have been third-party factory-tested for over 1 million cycles.

- The Liquid Smart® Alarm Sensor can be placed at any predetermined level. Every application is different and the adjustable alarm allows the sensor to be placed at the actual high liquid level which ensures that nuisance alarms do not occur.

- Not all jobs or applications are equal, which is why Oil Smart® technology allows for the flexibility of being paired with any submersible pump.

- Our capacitive technology allows for hand testing of the sensors, whereas conductive technology requires more steps to test when the system is installed.

- We offer the only true plug-and-play system in the industry. The Oil Smart® Plug-and-Play System (OSS-100) is the easiest elevator sump pump system to install on the market. With over 25 years of proven field results, Oil Smart® is the preferred solution by environmental specialists and engineers for preventing catastrophic oil spills.

Capacitive Technology:

No Moving Parts:

Adjustable Alarm:

Adaptable to Any Pump:

Easy Installation:

Custom Options

- 95-16 = 1.5” NC solenoid

- 95-17 = 1.5” NO solenoid

- 95-18 = 2.0” NC solenoid

- 95-19 = 2.0” NO solenoid

- OSA-05 = Oil containment tank alarm. Works in conjunction with alarm interlock pump shut down feature