Hydra® Transducer Control Panels

Quote Request

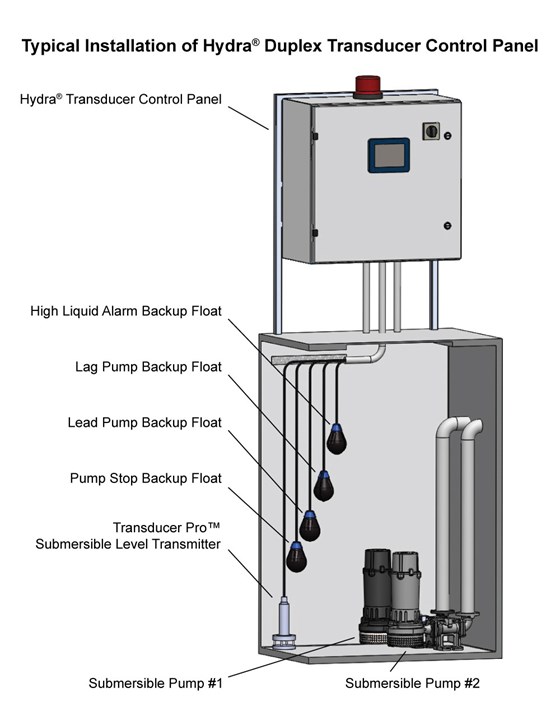

Our Hydra® transducer panels are a complete line of simplex, duplex, and triplex control panels that feature a versatile 7.0" HMI touchscreen controller ideal for sewage, wastewater, and dewatering applications. These control panels are equipped with our Pacific 2.0 software, which provides extensive system customization options and easy user guide tools with step-by-step instructions for the adjustable fields. These panels include a painted steel enclosure, upgraded pump protection, and remote monitoring dry contacts (Pump Fault and High Level). Hydra® control panels come standard with a two-year limited manufacturer's warranty.

Features

- NEMA 3R rated painted steel enclosure with a lockable latch; Dead front with inner door

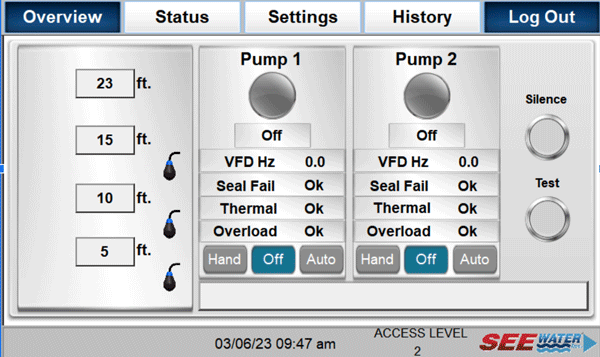

- HMI displays tank level, pump run light(s), pump run time(s), cycle count for each pump, and H.O.A. selector for each pump

- 7" screen with 800x480 resolution and a resistive film touch panel

- Simple transducer calibration setup

- Flip switch for transducer and float mode

- Adjustable set points:

- Simplex: Low Level, Stop, Start, High Level (Adjustable Lead pump start and stop set points)

- Duplex: Low Level, Stop, Lead, Lag, High Level; Duplex models feature two-pump alternation and high demand two-pump operation (Adjustable Lead and Lag pump start and stop set points)

- Alarm horn sounds at 85 decibels at 10 feet

- Alarm visible features: Red beacon alarm light

- Remote monitoring dry contacts: Pump Fault and High Level

- Upgraded pump protection: Motor protective switch(es) (Branch circuit protection, adjustable overload and disconnect)

- Pump run data logging: Records each pump event (Start time, stop time, and run duration)

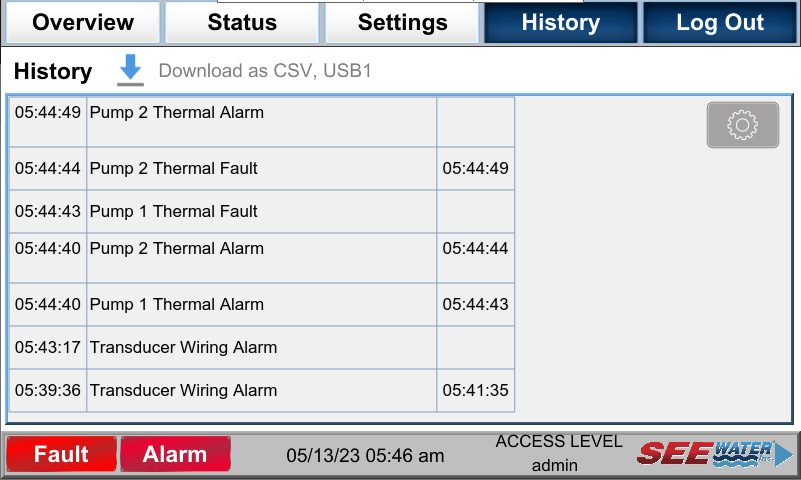

- Alarm/fault history: Data logging gives access to 250 fault conditions with date and time (Optional access to auto-save alarm history to USB drive)

- Advanced communications: Supports Modbus RTU/TCP, BACnet® IP/MSTP, and additional communication protocols. Allows for master and slave operation, remote monitoring and control of the pump station

- Multiple access levels for added security

- Panel and controls are UL listed for the United States and Canada

Add Pump Portal® remote pump monitoring to this control panel! LEARN MORE

Applications

- Sewage pump chambers

- Grinder pumps

- Sump pump basins

- Lift stations

Transducer Options

- 5 = Level Transducer, 5 PSI, Maximum Water Level 11 ft., Type: Wastewater

- 10 = Level Transducer, 10 PSI, Maximum Water Level 23 ft., Type: Wastewater

- 15 = Level Transducer, 15 PSI, Maximum Water Level 35 ft., Type: Wastewater

- 20 = Level Transducer, 20 PSI, Maximum Water Level 46 ft., Type: Wastewater

Custom Options

- 10X = Intrinsically Safe Level Transducer, 10 PSI, Maximum Water Level 23', Type: Wastewater, 50' Cable

- 20X = Intrinsically Safe Level Transducer, 20 PSI, Maximum Water Level 46', Type: Wastewater, 50' Cable

- 28 = Power On Dry Contacts

- 38 = Float Operation - Simplex

- 39 = Float Operation - Duplex

- 40 = Float Operation - Triplex

- AH = Anti-Condensation Heater

- BB = Battery Backup 5Ah

- CO = Convenience Outlet (User to supply 120 VAC)

- D100 = 10" HMI

- GR = Generator Receptacle; Includes Transfer Switch

- IS = Intrinsically Safe - Simplex (Float Operated System)*

- ISD = Intrinsically Safe - Duplex (Float Operated System)*

- IST = Intrinsically Safe - Triplex (Float Operated System)*

- LA = Lightning Secondary Surge Arrestor

- PM = Phase Monitoring

- PX = Pump Portal® Wireless Remote Panel Control and System Monitoring**

- RPRO = Radar Sensor, Max Level Range 32', 4-20mA + RS485, 12-30VDC, 50' Cable

- S3 = No Transducer or Float Option

- SF = Seal Failure Circuit and Indicator - Simplex

- SFD = Seal Failure Circuit and Indicator - Duplex

- SFT = Seal Failure Circuit and Indicator - Triplex

- SS4 = Upgraded Enclosure (304 Stainless Steel)

- SS6 = Upgraded Enclosure (316 Stainless Steel)

- UPRO = Ultrasonic Sensor, Max Level Range 15', 4-20mA, 12-30VDC, 50' Cable

*To include an intrinsically safe transducer, please contact us.

**Additional fee will apply for annual subscription.

HMI Navigation

The Hydra® features a comprehensive HMI touchscreen device with our Pacific 2.0 software that allows for complete monitoring of tank level status, alarm/fault history, and pump run data.

Overview

The HMI main menu displays live pump data and H.O.A. switch(es). This menu is your command center.

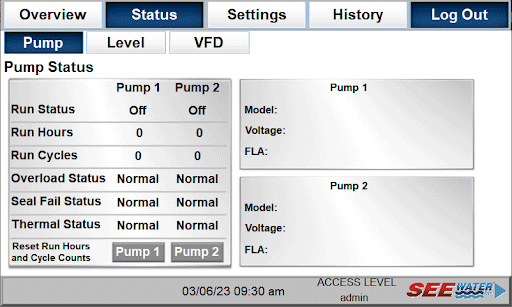

Pump Status Monitor

The Pump Status displays the status of all processes. Users can view Pump Fault, Run Time, and other necessary information.

Alarm/Fault History

Data logging gives you access to 250 fault conditions with the date and time. It also features an optional auto-save alarm history to USB drive.

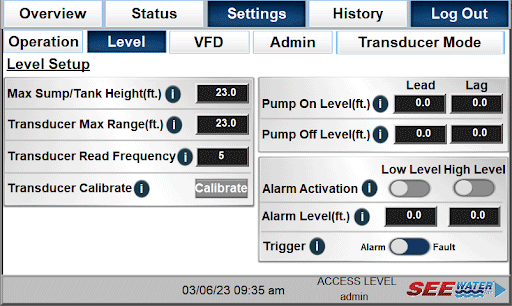

Level Setup

You can easily set up the Hydra®'s Pump On, Pump Off, High, and Low Level - all with the touch of a button!